Crusher bucket and electric jaw crusher

Equipment for crushing and recycling aggregates

Equipment for crushing and recycling aggregates

Maximum crushing efficiency

In the aggregates recycling industry, it is crucial to have the right equipment to optimise production and maximise site efficiency.

Crushing natural stone is an essential process in the construction and building materials industry. Natural stone is subjected to this process to obtain various materials used in a wide range of applications: aggregates for concrete and asphalt, paving materials, landscaping materials, cladding materials, and materials for slab production.

Our equipment is specialized in offering state-of-the-art solutions for crushing aggregates and reducing their volume: crusher buckets and electric jaw crushers.

Equipment that contributes to transforming materials from demolition and natural materials into resources ready for a new life in the buildings of tomorrow.

Reduction of operating costs

With the ability to crush and reduce volumes directly on site, this equipment helps to reduce material disposal and transport costs.

Increased productivity on the construction site

Thanks to their power and versatility, this equipment allows more production in less time, helping to increase the overall productivity of construction sites as well as giving the possibility to maximize the use of inert materials, reducing waste and optimizing resource recovery.

Application versatility

The crusher buckets and electric jaw crushers can handle aggregates of various sizes and types, offering a versatile solution for multiple needs.

In addition, the production of high-quality recycled materials is suitable for multiple uses, from use directly on the construction site to sale.

Respect for the Environment

Recycling aggregates reduces the accumulation of waste in landfills and contributes to preserving the environment by promoting sustainable practices.

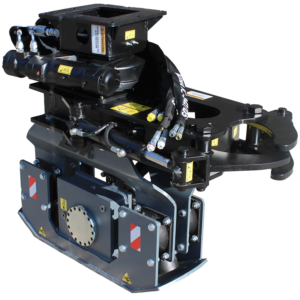

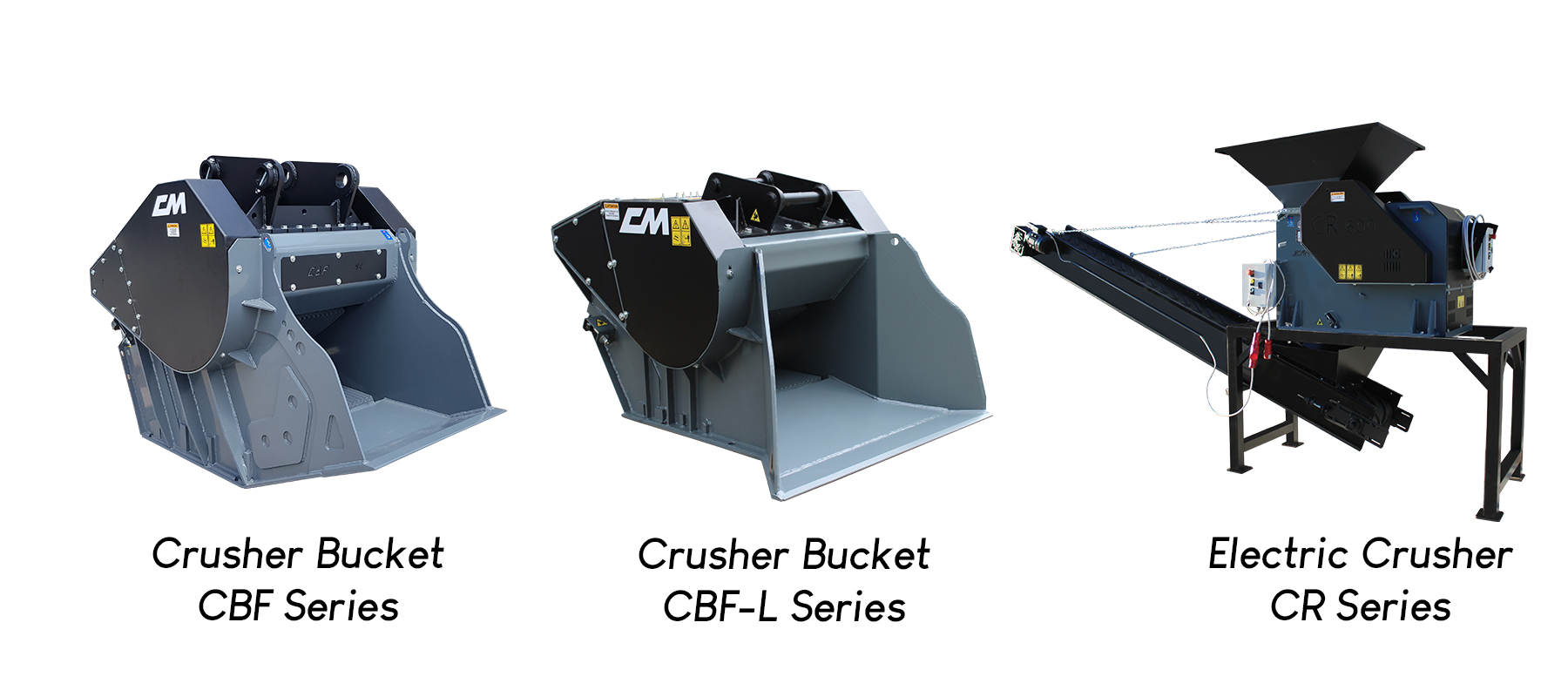

Crusher bucket – CBF Series

Suitable for excavators, backhoe loaders and wheel loaders, the CBF crusher bucket is equipped with centralised greasing for quick maintenance and crushing plates made of 18% manganese cast.

Crushing size from 15 to 135 mm.

Crusher bucket – CBF-L Series

Designed to be applied to small operating machines such as mini excavators, skid steer loaders and telescopic handlers, also equipped with centralised greasing and crushing plates made of 18% manganese cast.

Crushing size from 15 to 80 mm.

Electric jaw crusher – CR Series

A crusher powered by 380V electricity, easy to handle, it is suitable for all types of construction sites, whether difficult to reach or simply not equipped with machinery.

Crushing size from 10 to 80 mm.

Our crusher buckets and electric crushers can successfully crush all kinds of natural materials, regardless of their hardness on the Mohs scale.

All types of slate, sandstone, clay, basalt, limestone, granite, concrete, marble, porphyry, tuff, brick, gravel, plaster, and natural rock, from demolitions.

Demolition inert materials

Materials from building demolition or construction work.

Hardness can vary from 6 to 7 on the Mohs scale.

Slate

Considered a soft or semi-hard rock.

According to the Mohs hardness scale, basalt has a value between 2.5 and 4.

Basalt

Effusive rock of volcanic origin.

Hardness between 5 and 6.

Marble

Metamorphic rock is composed mainly of calcium carbonate.

Hardness between 3 and 4 on the Mohs scale.

Granite

Plutonic igneous rock is very common and widely used in various sectors, including construction and sculpture.

Granite usually has a hardness of 6 to 7.

Ferroalloy

Ferroalloys are metal alloys that contain iron as the main element, together with other metals or alloying elements.

They can reach up to 9 on the Mohs scale.

Porphyry

Porphyry is an intrusive igneous rock of volcanic origin.

It can have a hardness ranging from 6 to 7 on the Mohs scale.

Enquire now

Enquire now

Products

Products