Crushing, screening, sorting equipment

Efficient, Robust, Versatile

Efficient, Robust, Versatile

CM manufactures and markets recycling equipment with a specific focus on Crusher Buckets, Screening Buckets, and Sorting Grapples.

All CM equipment is designed to ensure maximum operational efficiency on the construction site with minimal maintenance. Compact, robust yet lightweight, they are the ideal tools for a streamlined and highly productive construction site.

In this way, CM equipment emerges as a reliable partner for the realization of efficient, safe, and cost-effective projects, contributing to the overall success of the construction site.

CBF-L Crusher Bucket

It is ideal for small operating machines, for skid steer loaders from 3 tonnes, and mini excavators from 4 tonnes upwards.

Output size adjustment from 15 to 135 mm.

Crushing plates are made of 18% manganese cast, interchangeable and reversible.

Adjusting the grain size is a simple operation, which can be done in 10 minutes directly on the site.

Body built 90% of Hardox.

CBF Crusher bucket

It is ideal for operating machines from 10 to 45 tons.

The crushing plates of the Crusher Buckets are made of 18% manganese casting, interchangeable and reversible and the output size is adjusted from 15 to 135 mm.

The jaw adjustment operation is done directly on-site in 10 min.

Made of HARDOX in the wearing parts.

CDS Screening Bucket

With rotors, for excavators from 2 to 30 ton, as well as for telescopic handlers, skid steer loaders, backhoe loaders and wheel loaders.

Rotors are easily replaced directly on-site. Also suitable for light crushing.

High productivity in the screening of moist soils.

CBR Rotary Screening Bucket

CM’s screening buckets can be applied to excavators from 1 to 50 tons, as well as skid steer loaders, telescopic handlers, tractors, wheel loaders and backhoe loaders.

Ideal for sorting material both before and after the crushing phase, they are particularly suitable for screening soil and gravel.

Made of HARDOX on the parts subject to the most wear and tear, they are equipped with an interchangeable basket that rotates in both directions.

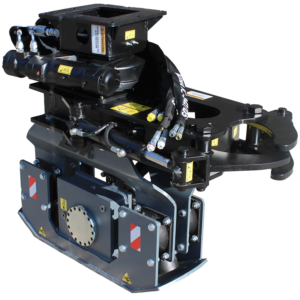

G Sorting grapples

Designed for excavators from 1.5 to 35 tons.

They have a high gripping force and thanks to their hydraulic rotation, the materials gripped are positioned at any point and with millimetric precision.

They have bolted cutting edges that allow fast replacement of the wearing parts.

These sorting grapples are also ideal for light demolition work.

Products

Products